Our quick deployment solution fits FMCG manufacturing & storage needs

Movement of raw materials to production, package materials, finished goods to storage.

Movement of raw materials to production, package materials, finished goods to storage.

Payback

Productivity increase

Reduction on manual dependency

Automation of production & storage process

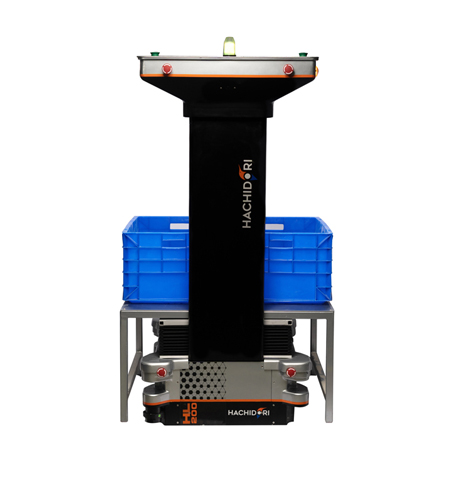

Unit Load Carrier : The Load On Top variant of AMR of 500 Kgs capacity. Moves material with minimal human involvement.

The Lift & move solution for lifting existing materials trolley and platform.

AMRs to lift & move standard Palletized materials. Deploy our Pallet lifting & movement solutions in moving raw materials to production line, WIP materials and from dispatch to warehouse.

Tugging solution with one or more wagons to be tugged – suitable for bulky light weight materials, off shape materials