Our versatile material movement solution fits all automotive industry needs

Flexible & Customizable material movement to integrate with your production plan.

Flexible & Customizable material movement to integrate with your production plan.

Payback

Productivity increase

Reduction on manual dependency

production plan & Execution

Safe Operations

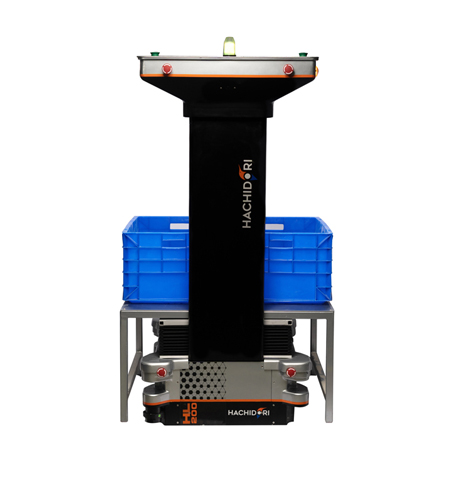

Unit Load Carrier : The Load On Top variant of AMR of 500 Kgs capacity. Moves material with minimal human involvement.

Tugging solution with one or more wagons to be tugged – suitable for bulky light weight materials, off shape materials

The Lift & move solution for lifting existing materials trolley and platform.

Docking with specific work bench and conveying materials from & to work bench.